Product Description

1.General introduction:

Powder coatings are mixed with a certain proportion of the resin, fillers, curing agents and other additives, then prepared by hot extrusion ,crushed and sieved.The products are stable at room temperature storage, then baking heat melted and solidified to form a smooth and bright permanent coating to achieve the purpose of decoration and corrosion.

2.Feature:

1).The products are non-toxic, solvent-free and non-toxic volatile substances,there are no intoxication, no fire, no "three wastes" emissions and other pollution problems, in full compliance with national environmental laws.

2). Raw material utilization is high, the highest utilization rate even more than 99%.

3). After being pre-coated handle, disposable construction, without primer,you can get a sufficient thickness of the coating, easy to automate operation, high production efficiency, reduce costs.

4). Dense coating adhesion, good impact strength and toughness, high coverage corners, with excellent resistance to chemical corrosion and electrical insulation properties.

5).Powder coatings storage and transport are safety and convenience.

3.Product series:

The products include high light ( above 86%),glazed (76%-85%),matte(20%-50%),low light (below 20%). We also offer a variety of shiny products according to the needs of users.

4.Powder physical properties:

Proportion : 1.2-1.8 (depending on the color and gloss ) .

Particle size distribution: 100% less than 125 microns (more than 85% between 60 to 90).

Liquidity(180°C):22~35mm.

Curing conditions:200°C,10 minutes.

5.Average coverage:

8-10m2/kg, the membrane is 60μm(calculate by 100% utilization rate of powder coating).

6.Packing:

Carton packaging, lined with double polyethylene bag, net weight 25 kg.

7.Storage requirements:

Store below 30 °C, ventilated, dry, clean room, not near the fire, heat, direct sunlight, open dumps is prohibited.Under this condition, the powder can be stable for 12 months, more than the storage period may be re-examined, such as the results meet the requirements, can still be used.

8.Health and safety:

This product is non-toxic.

In the course of inhalation of dust should be avoided. The operators should wear appropriate dust mask and glasses.

9.Coating performance

| Epoxy Resin Powder Coatings Epoxy resin powder coating is a kind of thermosetting powder coating with corrosion resistance and toughness. It consists of epoxy resin, pigments and fillers, additives and curing agents. It has many advantages, such as strong adhesion, high hardness, scratch resistance, corrosion resistance, low melting viscosity, good leveling, no pinholes and shrinkage defects in the film, many kinds of patterns and colors, and can be prepared matte, bright, pattern, hammer pattern, etc. The thickness of the film can reach 50-300 um in one painting, and it can be recycled for uncoated powder. Mainly used in equipment and facilities, refrigerators and refrigerators, washing machines, radio, lampshades, bicycles and motor frame, automobile steering wheel, components and body, agricultural machinery equipment, pipeline external paint and so on. | ||||

| physical property | proportion | 1.62+/-0.05, depending on color and luster | ||

| granularity | 100%100 micron. If you have special request, please notify in advance. | |||

| Mobility | 25-30mm | |||

| Performance Index of Coating Film | performance | Testing standard | detection result | |

| 60-degree gloss meter | GB/T9754-88 | Highlight85--100%Matte15--50% | ||

| No light 5-10% | ||||

| impact test | ISO6272 | GB/T1723-1993 | 1250px/kg | |

| Cupping test | ISO1520 | GB/T9753-1988 | >6mm | |

| adhesion | ISO2409 | GB/T9286-1998 | Level 0 | |

| Bending test | ISO1519 | GB/T6742-1986 | 2mm | |

| Pencil hardness | ASTMD3363 | GB/T6739-1996 | 2H~3H | |

| Salt spray test | ISO7253 | GB/T1771-1991 | >1000h | |

| Moisture resistance | ISO6270 | GB/T1740-1979 | >1000h | |

| Acid resistance (5% HCL) | GB/T9274-1988 | >300h | ||

| Alkali resistance (5% NaoH) | GB/T9274-1988 | >300h | ||

| Oil Resistance (120 # Gasoline) | GB/T1734-1993 | >300h | ||

| Note: 1. The above tests were carried out with 0.8mm rust and oil removal cold-rolled steel plate under experimental conditions. The coating thickness is about 70um. | ||||

| 2. The performance index of the above coatings may decrease slightly with the decrease of gloss. | ||||

| Construction condition | Curing conditions | Standard curing: 180 +5 C/15-20 minutes (solid temperature of workpiece to help coatings fully curing) | ||

| Pre-processing | Different substrates before use (phosphating, sandblasting, shot peening) | |||

| Spray | Corona electrostatic spraying; friction electrostatic spraying; electrostatic fluidized spraying (required first); fluidized bed hot dipping (required first); other spraying methods (required first) | |||

| Theoretical coverage | 12.0 M2 @ 60 micron (depending on type and color) | |||

| Scope of application | indoors and outdoors | |||

| Other matters | Packaging and transportation | 20kg/box, lined with polyethylene plastic bags, non-hazardous goods, can be transported in various ways, but should avoid direct sunlight, damp and heat, avoid contact with chemical substances. | ||

| Storage requirements | Store in a ventilated, dry and clean room at 30 C. Keep away from fire sources, heating, direct sunlight and stacking in the open air is strictly prohibited. Under these conditions, the powder can be stored stably for 6 months. Over the storage period, it can be re-examined, and if the results meet the requirements, it can still be used. All containers must be re-packaged and returned to the original packaging after use. | |||

| Health safety | Containers should be kept sealed and not close to fire or heating. Avoid inhaling powder. Food and smoking are prohibited in storage areas. The builder should wear anti-static shoes and keep grounding. Coatings attached to the skin can be washed with soap. | |||

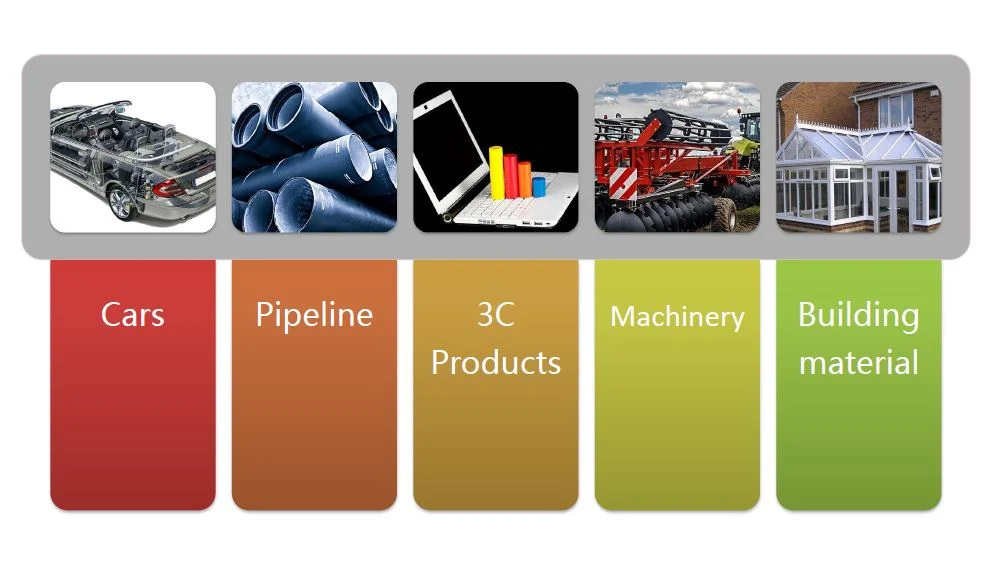

Application

Product process pictures

Testing process pictures

Company information

| Jiangsu Changsong Technology Development CO., Ltd |

| Business Type:Manufacturer/Factory |

| Year established:1991 |

| Main Markets: Asia Pacific, Middle East, Europe, south & north America |

| Advantage:our factory is close to Shanghai port,convenient transportation;trade assurance supplier; excellent research and development group;professional testing facilities; reliable quality and good service and reasonable price |

Purchase Note:

| 1.M.O.Q : |

| The minimum order is2000kg ,each color ≥ 100kg |

| 2.Colors: |

| RAL color :we usually use RAL colors that is widely used in paint industry and easily find in market |

| Custom color : Color matching is available , if you have colors model ,please send to us for matching . |

| 3.Prices: |

| Prices depend on the colors and using environment ,for prices please tell us the colors and using environment (indoor use or outdoor use). |

| 4.Time of delivery : |

| Production will take about 5-8 days after receipt of prepayment,this is subject to the quantity . |

| 5.Payment : |

| Prefer T/T IN ADVANCE PAYMENT; 30% T/T prepayment , 70% T/T before shipment (or against BL copy) or LC at sight . |

| 6.Samples: |

| 1kg powder sample is available for each color for your testing. |

| Sample is free of cost,but if you pay for the air freight we will highly appreciate. |

Contact us:EVA ZHANG

Jiangsu Changsong Technology Development Co., Ltd

Mb :+86 18662361801

Website:changsongcoating.en.made-in-china.com